General System Description

This section provides general information about the system. It identifies the interfaces between the system and its environment, describes the user characteristics, and lists the system constraints.

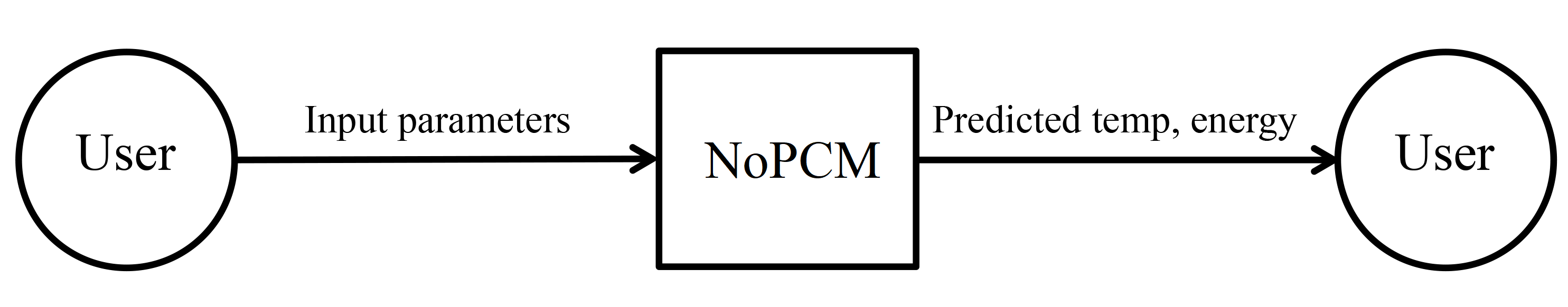

System Context

Fig:SysCon shows the system context. A circle represents an external entity outside the software, the user in this case. A rectangle represents the software system itself (SWHSNoPCM). Arrows are used to show the data flow between the system and its environment.

SWHSNoPCM is mostly self-contained. The only external interaction is through the user interface. The responsibilities of the user and the system are as follows:

-

User Responsibilities:

- Provide the input data to the system, ensuring no errors in the data entry

- Take care that consistent units are used for input variables

-

SWHSNoPCM Responsibilities:

- Detect data type mismatch, such as a string of characters instead of a floating point number

- Determine if the inputs satisfy the required physical and software constraints

- Calculate the required outputs

User Characteristics

The end user of SWHSNoPCM should have an understanding of undergraduate Level 1 Calculus and Physics.

System Constraints

There are no system constraints.